With a continued focus of sustainable and energy efficient building design, more attention is being paid to the thermal performance of building enclosure assemblies. Providing a higher level of thermal resistance in the building enclosure may seem as straightforward as just adding insulation, but when building with conductive elements like steel, achieving higher thermal performance levels can be elusive.

With a continued focus of sustainable and energy efficient building design, more attention is being paid to the thermal performance of building enclosure assemblies. Providing a higher level of thermal resistance in the building enclosure may seem as straightforward as just adding insulation, but when building with conductive elements like steel, achieving higher thermal performance levels can be elusive.

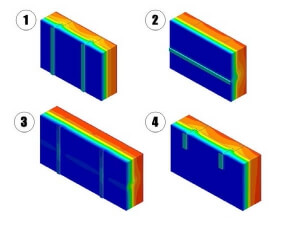

When cladding is attached to back up steel stud walls, the attachments bypass the exterior insulation. These attachments, usually made of steel, can create significant heat flow paths. While there are some systems that minimize the bridging effect, many of the common attachment methods are not very efficient from a thermal perspective.

The Questions

Building energy standards, such as ASHRAE 90.1, force recognition of the impact of thermal bridging. Table A3.3 in ASHRAE 90.1 provides effective assembly U values for stud walls that consider the effects of the steel studs through the stud cavity. These values, however, are for assemblies with different levels of continuous insulation outboard of the studs (basically assuming you have the full nominal value of the exterior insulation). The table does not provide guidance in addressing the thermal impact of the cladding support elements passing through the exterior insulation. This raises some critical questions:

- What are the effective R- and U-values of your steel stud assembly walls and do they meet code requirements?

- What is the difference in thermal performance of different cladding attachment arrangements?