Landfill or Waste-to-Energy Technology? CVRD Asks “What is Best for Our Future?”

The cost of operating landfills and the environmental concern is causing municipalities to evaluate their approach to waste management. With so many existing and emerging waste technologies, it’s a big job deciding what is the most practical, cost-effective and environmentally friendly plan for the future.

Morrison Hershfield recently met with the Comox Valley Regional District (CVRD) Select Committee (BC, Canada) to present the findings of a research study to determine the most cost-effective solution for the future management of residual waste in the Regional District.

The Options

The study involved a review of solutions available to CVRD to alleviate the rising costs of landfilling and environmental effects over the short and long term. The focus was on the residual waste stream that is currently landfilled. With recycling and composting already being optimized, the CVRD requested that Waste-to-Energy (WtE) options be considered. WtE has the potential to provide the most diversion from landfill. Our study evaluated several WtE technologies, including:

- Conventional combustion systems.

- Gasification and pyrolysis technologies.

- Refuse Derived Fuel (RDF).

Conventional combustion is the traditional form of WtE and involves the incineration of waste with the subsequent recovery of energy in the form of heat or steam for making electricity.

Gasification and pyrolysis technologies are advanced thermal recovery methods, first converting the waste into burnable gases or liquids, and then using these to generate electricity or as feedstock for chemical processes.

RDF technologies process various waste types to produce a homogeneous material that can be sold to third parties as fuel. An example of this is using RDF in cement kilns to offset the use of coal.

At the end of the analysis, we shortlisted three technologies; a traditional combustion WtE, and two Mixed Waste Processing Facilities (MWPF) that produced RDF for combustion by third parties. The MWPF also increased recycling, and one of the technologies included pyrolysis of plastics into diesel fuel.

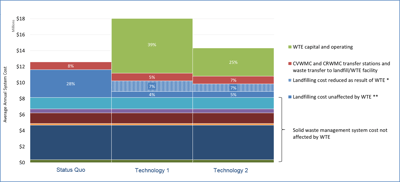

Working closely with the CVRD, Morrison Hershfield established evaluation criteria specific to their needs and priorities. We then modeled the technologies in terms of costing and waste reduction and presented the technologies based on their contribution to diversion. The analysis was conducted in the context of a full cost analysis and compared to the status quo of landfilling and recycling.

Modeling outcomes were presented to the CVRD stakeholder committee in person, and feedback incorporated into an expanded analysis of full waste management system costs.

The Results

At this time the status quo is still more cost effective for CVRD than going with one of the alternative technologies. However, some of the technologies show great potential for a time when costs can be more closely defined and markets for the products are confirmed. The presentation gave the Regional District directors a clear understanding of their current situation, the development path of various technologies, direction on which technologies to watch and how to implement them in the future to move away from landfills.

A Team Effort

Our thorough understanding of CVRD’s needs and waste management system, experience with assessing traditional and emerging WtE technologies, and planning expertise helped to solidify the findings of the report. We also had full support from members of the Regional District Board’s Select Committee, and assistance from the CVRD staff to execute the work.

“The success of this project was possible through close cooperation with our client. The Regional District was essentially part of the team working towards the common goal of identifying a cost-effective, future-oriented waste management system,” said Konrad Fichtner, Waste Practice Lead for Morrison Hershfield.

What’s Next?

CVRD will closely monitor the development of a technology that converts plastics into diesel fuel being implemented in Nova Scotia. Within the next 12-24 months, they will have more data to re-evaluate the situation and potentially consider an alternative to landfilling.

Morrison Hershfield is looking forward to an opportunity to help the CVRD re-evaluate and run the financial model in the future with the new data.

In addition to the WtE study, we are currently helping CVRD find solutions on three other waste projects:

- Implementation of a composting facility.

- Review of the waste management planning process.

- Assessing landfill design.

To learn more about this project and other CVRD news, click here.

Posts by Topic

Topics

- 5G (1)

- ACEC (3)

- Active Transportation (5)

- AFP/P3 (6)

- Alberta (5)

- Anniversary (1)

- approvals (1)

- Architect (2)

- Atlanta (2)

- Awards (62)

- Biophysical Sciences (1)

- Board of Directors (1)

- Bridge Rehabilitation (3)

- Building and Facilities Engineering (2)

- Building Energy (25)

- Building Envelope (48)

- Building Science (65)

- Calgary (2)

- Canada 150 (1)

- Canstruction (2)

- Capabilities (1)

- Carbon emissions (2)

- Carbon Pathfinder Tool (1)

- Carson Awards (5)

- Charity (13)

- Climate Adaption (7)

- climate change (7)

- Code and Life Safety (8)

- Commercial Buildings (4)

- Commissioning (11)

- Construction (2)

- Construction Administration (5)

- Consulting Engineering (1)

- Critical Facilities (33)

- CSR (24)

- Culture (5)

- Dallas (1)

- Data Center (22)

- Data Center Commissioning (9)

- Data Center Design (12)

- design (9)

- Design Build (1)

- DSSP (1)

- edgecomputing (1)

- edgetechnologies (1)

- Edmonton (4)

- Electrical (24)

- Electrical engineering (8)

- Energy (8)

- Engineers Canada (5)

- Environmental (36)

- Environmental Compensation (1)

- Environmental Impact Assessment (3)

- environmental planner (3)

- Environmental Planning (5)

- ETFE (1)

- Event (12)

- Existing Buildings (6)

- Facade Engineering (4)

- Ferry Docks (2)

- FIDIC (3)

- fisheries biologist (1)

- Flood Mapping (1)

- Florida (1)

- Forensic Investigation (1)

- Fundraising (11)

- garage (2)

- Gender Diversity (8)

- Gender Intelligence (3)

- Geometric Design (2)

- Government (14)

- Hospitality (1)

- Houston (4)

- Hydro (2)

- India (1)

- industrial (4)

- Infrastructure (28)

- Innovation (1)

- interchange (1)

- IWD (2)

- IWD2021 (1)

- Land Development (8)

- Landfill (4)

- Manitoba (1)

- MCF (3)

- Mechanical (21)

- Mechanical Engineering (1)

- MEP (1)

- mission critical (10)

- Moncton (1)

- Motivational MH'er (1)

- Multi-Use Pathways (1)

- Municipal Infrastructure (5)

- municipal solid waste (2)

- MUP (1)

- New Brunswick (1)

- New Hire (17)

- New Role (3)

- Newsroom (121)

- northern communities (2)

- NVTC (2)

- ontario (1)

- Operations Consulting (8)

- Ottawa (2)

- Panel (3)

- People (124)

- Project Management (6)

- QAP (1)

- Rail (1)

- Reconstruction (1)

- regulatory (1)

- Renewable Energy (2)

- resiliency (3)

- Risk Management (1)

- Roads and Highways (3)

- Salt Lake City (1)

- Seattle (1)

- Security (4)

- Social Responsibility (30)

- Solid Waste (11)

- solid waste management (5)

- St Johns (2)

- Stantec (1)

- Structural (14)

- Sustainability (23)

- Telecom (9)

- Texas (1)

- Toronto (13)

- towers (1)

- Traffic Assessment (2)

- Transfer Station (1)

- Transit (13)

- Transit Consultant (3)

- Transit Infrastructure (3)

- Transit Planning (2)

- Transportation (30)

- Transportation Engineering (8)

- transportation structures (2)

- TTC (1)

- Vancouver (6)

- Virginia (2)

- Washington DC (3)

- Waste to Energy (2)

- Water & Wastewater (8)

- Water Resources (3)

- wellfield (1)

- wellness challenge (1)

- Whistler (1)

- Whitehorse (1)

- Wireless (2)

- Women in Engineering (5)

- Yukon (5)